Choosing the right bedding mortar

To get the best performance from our manhole covers, gratings and surface boxes we recommend using the appropriate materials to install them, in particular a bedding mortar that has been specifically developed for this purpose.

A suitable mortar should ideally be non-shrink, be rapid set and have a quick strength gain. We strongly advise against using standard concretes or sand and cement mortars for this purpose.

A. Mix material

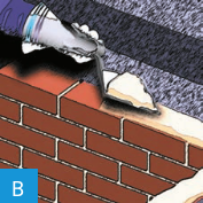

B. Bedding layer

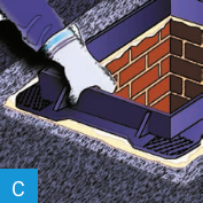

C. Seat casting

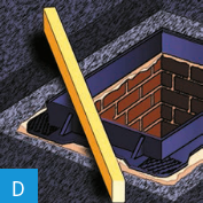

D. Level casting

E. Check gaps under flange

Ensure that there are no visible gaps under the flange and smooth bedding material with trowel both inside and outside of chamber.

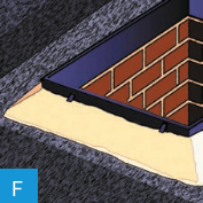

F. Envelope flange

Use the remaining mortar to envelope the flange paying particular attention to the corner areas. Smooth out the mortar with a trowel to ensure good bonding with the casting and to avoid any initial cracks in the bedding material.

G. Backfill

Check that the bedding material has hardened and backfill with asphalt. Ensure that the asphalt is properly compacted.